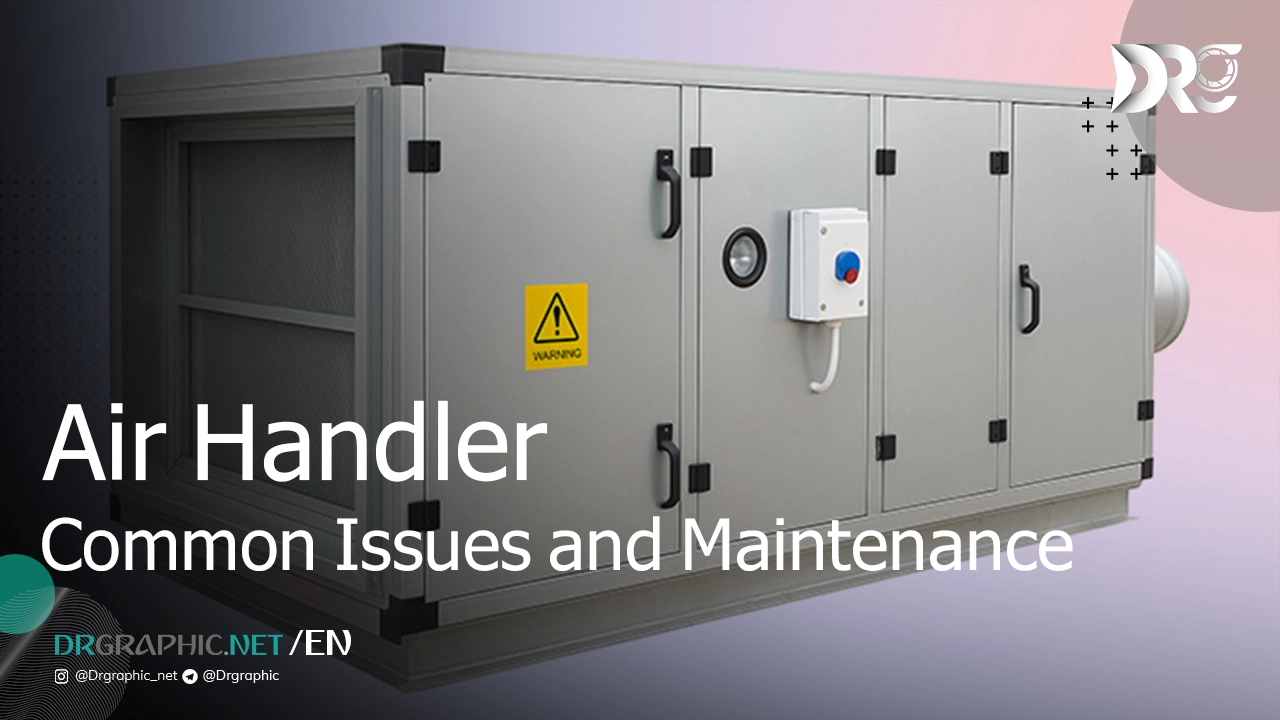

Air handlers, also known as air handling units (AHUs), are HVAC systems responsible for regulating indoor air quality, temperature, and humidity. An air handler ensures that buildings’ air—from commercial offices to hospitals and industrial facilities— remain comfortable, healthy, and safe for occupants. Despite their robust design, air handling units are not immune to wear and tear. Like any mechanical system, they require regular care to perform optimally. Understanding the common problems that can arise, as well as implementing a preventive maintenance routine, is crucial for maximizing air handlers’ efficiency and lifespan.

Why Air Hansler Regular Maintenance Matters?

The importance of regular maintenance for air handlers cannot be overstated. A well-maintained air handler not only operates more efficiently but also significantly reduces the risk of unexpected breakdowns that can disrupt building operations. Neglecting maintenance often leads to increasing energy consumption. In this case, components (fans and coils) must work harder to achieve the desired air conditions. This extra strain can result in premature wear, leading to costly repairs or even the requirement of full replacement.

Regular AHU maintenance also plays a critical role in maintaining high indoor air quality. An air handler circulates air throughout the building, and any buildup of dust, mold, or bacteria within the system can compromise the health of occupants. Clean filters, properly functioning coils, and well-maintained dampers ensure that the delivered air is fresh, safe, and comfortable. Furthermore, many air handling unit manufacturers require regular maintenance to validate warranties, making it both a practical and economic necessity.

Common Air Handler Issues

Even with careful use, air handling units can experience a range of issues. Some of the most frequent problems stem from the accumulation of dust, debris, or general mechanical wear. Here are the most frequently occurring air handler issues:

- Dirty or clogged filters are perhaps the most common issue. When filters become blocked, airflow is restricted, causing the fan motor to work harder. This issue also increases energy consumption and reduces overall system efficiency.

- Fans and blowers are another area prone to trouble. Over time, motors can lose efficiency, bearings may wear out, and belts can loosen or crack. These problems often manifest as unusual noises, vibrations, or reduced airflow. They crash the system’s ability to maintain consistent indoor conditions.

- Coils, whether used for heating or cooling, are critical components that can also develop concerns. Dirty coils restrict heat exchange, reducing the system’s ability to cool or heat air effectively. In more severe cases, coils can corrode or leak, potentially leading to water damage and mold growth within the unit.

- Dampers and their associated actuators can fail or become misaligned, resulting in uneven distribution of air throughout the building. This can cause hot or cold spots, negatively affecting occupant comfort.

- Condensate drainage is another area that frequently causes problems. If drains become blocked, water can accumulate, leading to leaks, corrosion, or microbial growth.

- Finally, control systems and sensors, which regulate temperature, humidity, and airflow, may malfunction or become miscalibrated, causing inconsistent operation and inefficient energy use.

How to Fix or Prevent Air Handling Units Problems?

Addressing air handler problems effectively requires both reactive and preventive strategies.

- Filters should be checked and replaced on a regular schedule, typically every one to three months, depending on usage and environmental conditions. This simple step ensures that airflow remains unimpeded and protects the fan motor from unnecessary strain.

- Fan motors and blowers should be inspected periodically. Bearings can be lubricated, belts adjusted or replaced, and any signs of wear addressed promptly.

- Coil maintenance is equally important; cleaning the coils, inspecting for corrosion, and repairing any leaks will maintain efficient heat transfer and prevent water-related issues.

- Damper and actuator inspection is essential for maintaining balanced airflow. Misaligned dampers should be adjusted, and faulty actuators should be replaced to ensure that conditioned air reaches all areas of the building as intended.

- Condensate drains and pans should be cleared of debris and regularly sanitized to prevent mold growth and water damage.

- Finally, control systems and sensors should be calibrated periodically, and software updates applied if possible, to maintain accurate system monitoring.

Air Handler Maintenance Tips

Preventive maintenance is the cornerstone of a reliable and long-lasting air handler. A structured maintenance and service program typically includes tasks weekly, monthly, quarterly, and annually. Weekly or daily checks might involve inspecting overall system operation and looking for unusual noises or vibrations. Monthly and quarterly activities include filter replacement, cleaning coils, lubricating moving parts, and testing sensors. Annual maintenance and service involve a comprehensive inspection by a qualified technician, including detailed checks of electrical components, fans, dampers, and overall airflow performance.

Implementing a preventive maintenance approach ensures that potential problems are caught early, minimizing downtime and costly emergency repairs. It also extends the lifespan of the AHU, making it a cost-effective investment for building operators. Moreover, preventive maintenance enhances energy efficiency, which can significantly reduce utility bills over the long term.

Benefits of Proper AHU Maintenance

Proper maintenance of air handling units provides multiple benefits. The boldest of which are as follows:

- First and foremost, AHU maintenance enhances the energy efficiency of the system, reducing electricity consumption and lowering operating costs.

- Well-maintained air handlers also operate more quietly and consistently, providing a more comfortable indoor environment.

- Preventive AHU maintenance reduces the frequency and severity of breakdowns, ensuring that occupants experience minimal disruption.

- Air quality is another major advantage. Clean filters, coils, and drainage systems prevent the accumulation of dust, mold, and bacteria, ensuring that indoor air is healthy and safe for building occupants. For commercial buildings, hospitals, and laboratories, maintaining air quality is not only for comfort; it is often a regulatory requirement.

- Finally, proper maintenance preserves the overall investment in the HVAC system. By avoiding unnecessary repairs and extending the life of the air handling unit, building owners and managers can achieve a higher return on their investment and reduce the total cost of ownership over time.

Air Handlers Maintenance and Common Issues in Brief

Air handling units are essential for providing comfortable, healthy, and energy-efficient indoor environments. However, they are complex systems that require regular attention to operate at their best. Understanding the common problems that can arise, such as clogged filters and dirty coils, or fan malfunctions and control issues, is the first step in effective maintenance. Implementing a preventive maintenance program ensures that these issues are addressed before they escalate, improving efficiency, reducing operating costs, and extending the system’s lifespan. While troubleshooting an air handling unit, you may need a hand from an expert HVAC professional. In that case, don’t hesitate to call DamaTajhiz Co. In the following, you’ll get to know this reputable company in detail.

DamaTajhiz Co., Specialized in HVAC Systems

DamaTajhiz Co., founded in 2004 by Mr. Majid Zavvarian, is a specialized center offering expert guidance on the selection, pricing, and purchase of Heating, Ventilation, and Air Conditioning (HVAC) systems. Since its establishment, a team of professional and experienced engineers has been providing reliable consultations to clients worldwide, helping them to choose the most efficient equipment, maintain and service their systems, and purchase building essentials at the most competitive prices in the market.

At DamaTajhiz, customers can order a complete range of HVAC and MEP products, including air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, cast-iron and steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and boiler burner in Iraq, Turkmenistan, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Kuwait, Uzbekistan, Qatar, etc., and delivering them quickly and safely to major cities including Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Doha, Amman, Sulaimaniyah, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, and Baku, among others — ensuring prompt delivery to your location in the shortest possible time.

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 1

No votes so far! Be the first to rate this post.